Industrial waste management is the collection, transportation, and disposal of hazardous waste. In order to prevent contamination of the surrounding area, hazardous waste must be disposed of in a modern secure facility. This costly process involves the preparation and transport of large quantities of waste. There is also an option for on-site cleanup, where a new facility is built at the original site and water pollution treatment is performed. Full containment is used by some plants. This involves reducing groundwater flow and capping the site.

Construction and demolition debris

Construction and demolition waste are industrial wastes that are generated during construction. Most construction waste can legally go to landfills. Some waste can be illegally dumped on the ground or in waters bodies in certain locations. Additionally, this waste is illegal and can cause harm to the environment. It also violates laws protecting commerce and human safety. The United States alone sees millions of tons annually of building-related rubbish being dumped in landfills every year. As such, it is essential for construction waste management to adhere to strict regulations.

Fabrication of waste

Recycling is an integral part of a circular economy. In recent years, the use of recycled materials has increased significantly, as are the amount of energy and materials saved. There are many technologies available today to assist manufacturers in managing and recycling their waste. Some technologies can help manufacturers reduce their costs while increasing their output.

Agriculture waste

Agriculture waste can be defined as solid waste generated by agricultural processes. This includes wastes generated during animal and crop production, food and meat processing, and waste from animal feeding. The agricultural industry produces solid wastes from animal carcasses, crop residues, animal feeding waste, feathers, and hoofs.

Chemical waste

Majority of chemical waste is dangerous, which means it poses a risk for the environment or human life. There are regulations in place that can help you safely dispose of hazardous materials. Environmental penalties can also be imposed for improperly managing hazardous wastes. Some types of waste, however, are not considered to be hazardous and are therefore not subject to the same regulations.

Mine waste

Mining creates huge amounts of waste. It is essential that miners know how to properly manage and dispose this waste. Erich Lawson writes as a freelancer. He is also a passionate environmentalist. He writes on a range of recycling topics, including how to manage industrial and hazardous waste, as well as compactors and balers. He loves helping businesses reduce their garbage costs and increase their revenue through recycling.

Oil & Gas Waste

For oil and gas wastes, there are specific requirements for industrial waste management. Most common oil & gas hazardous wastes are drilling wastes as well as production fluids and finished waters. These wastes need to be disposed of with care in order to minimize their effect on the environment.

Nuclear waste

Solid waste must be properly disposed of to protect public health and improve the environment. For waste with a short half life (less than 100 year), it can be safely disposed in engineering modules like reinforced concrete trenches, tiles holes and stone-lined trenches. Near Surface Disposal Facility, (NSDF), is built under the ground. The waste is buried for up to 500m below the ground. Multi-barrier systems are used to stop radioactive waste from spreading.

Other

The global industrial waste management market has many players, both domestic and international. The industry's key players are focused on innovation in waste management. The market for industrial wastewater management encompasses solid, liquid, as well as gaseous, wastes from different industrial sectors. Wastes from these sectors may include hazardous and non-hazardous materials. Many of these materials end up in landfills or being incinerated. These practices can be very harmful to wildlife and the environment.

FAQ

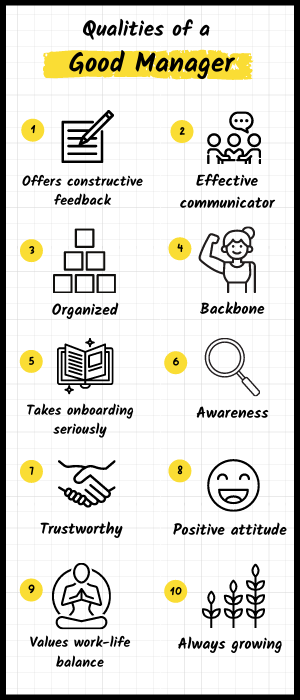

How do you manage your employees effectively?

Achieving employee happiness and productivity is key to managing them effectively.

It is important to set clear expectations about their behavior and keep track of their performance.

To do this successfully, managers need to set clear goals for themselves and for their teams.

They must communicate clearly with their staff. And they need to ensure that they reward good performance and discipline poor performers.

They should also keep records of all activities within their team. These include:

-

What was accomplished?

-

What was the work involved?

-

Who did it?

-

How did it get done?

-

Why was this done?

This information can help you monitor your performance and to evaluate your results.

How does Six Sigma function?

Six Sigma uses statistical analysis for problems to be found, measured, analyzed root causes, corrected, and learned from.

First, identify the problem.

Next, data will be collected and analyzed to determine trends and patterns.

The problem is then rectified.

Finally, data is reanalyzed to determine whether the problem has been eliminated.

This continues until the problem has been solved.

What is the difference between leadership and management?

Leadership is about influencing others. Management is about controlling others.

A leader inspires his followers while a manager directs the workers.

Leaders motivate people to succeed; managers keep workers on track.

A leader develops people; a manager manages people.

It can sometimes seem difficult to make business decisions.

Complex systems with many moving parts are the hallmark of businesses. It is difficult for people in charge of businesses to manage multiple priorities simultaneously and also deal with uncertainty.

It is important to understand the effects of these factors on the system in order to make informed decisions.

To do this, you must think carefully about what each part of the system does and why. It is important to then consider how the individual pieces relate to each other.

You need to ask yourself if your previous actions have led you to make unfounded assumptions. If so, it might be worth reexamining them.

If you're still stuck after all this, try asking someone else for help. They might see things differently than you and may have some insights that could help find a solution.

What is the difference between TQM and Six Sigma?

The major difference between the two tools for quality management is that six Sigma focuses on eliminating defect while total quality control (TQM), on improving processes and decreasing costs.

Six Sigma is a method for continuous improvement. It emphasizes the elimination of defects by using statistical methods such as control charts, p-charts, and Pareto analysis.

This method attempts to reduce variations in product output. This is done by identifying and correcting the root causes of problems.

Total quality management refers to the monitoring and measurement of all aspects in an organization. It also includes the training of employees to improve performance.

It is often used to increase productivity.

What is TQM?

The industrial revolution was when companies realized that they couldn't compete on price alone. This is what sparked the quality movement. To remain competitive, they had to improve quality as well as efficiency.

Management responded to the need to improve, and developed Total Quality Management (TQM). This focused on improving every aspect of an organization’s performance. It included continuous improvement processes, employee involvement, and customer satisfaction.

Statistics

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

- Our program is 100% engineered for your success. (online.uc.edu)

- As of 2020, personal bankers or tellers make an average of $32,620 per year, according to the BLS. (wgu.edu)

- This field is expected to grow about 7% by 2028, a bit faster than the national average for job growth. (wgu.edu)

External Links

How To

How can you implement a Quality Management Plan?

QMP (Quality Management Plan) is a system to improve products and services by implementing continuous improvement. It emphasizes on how to continuously measure, analyze, control, and improve processes, product/service, and customer satisfaction.

QMP stands for Quality Management Process. It is used to guarantee good business performance. QMP improves production, service delivery, as well as customer relations. QMPs should encompass all three components - Products and Services, as well as Processes. When the QMP includes only one aspect, it is called a "Process" QMP. When the QMP focuses on a Product/Service, it is known as a "Product" QMP. If the QMP focuses on Customer Relationships, it's called a "Product" QMP.

Scope is the most important element in implementing a QMP. Strategy is the second. These elements are as follows:

Scope is what the QMP covers and how long it will last. This scope can be used to determine activities for the first six-months of implementation of a QMP in your company.

Strategy: This is the description of the steps taken to achieve goals.

A typical QMP includes five phases: Design, Planning, Development and Implementation. Below is a description of each phase:

Planning: This stage is where the QMP objectives are identified and prioritized. To understand the expectations and requirements of all stakeholders, the project is consulted. The next step is to create the strategy for achieving those objectives.

Design: This stage is where the design team creates the vision, mission and strategies necessary for successful implementation of QMP. These strategies are put into action by developing detailed plans and procedures.

Development: This is where the development team works to build the capabilities and resources necessary for the successful implementation of the QMP.

Implementation: This refers to the actual implementation or the use of the strategies planned.

Maintenance: It is an ongoing process that maintains the QMP over time.

Additionally, the QMP should include additional items:

Stakeholder Involvement: Stakeholders are important for the success of the QMP. They are required to actively participate in the planning, design and development of the QMP, as well as the implementation and maintenance phases.

Project Initiation: The initiation of any project requires a clear understanding of the problem statement and the solution. The initiator must know the reason they are doing something and the expected outcome.

Time Frame: It is important to consider the QMP's time frame. A simple version is fine if you only plan to use the QMP for a brief period. If you are looking for a longer-term commitment, however, you might need more complex versions.

Cost Estimation is another important aspect of the QMP. It is impossible to plan without knowing what you will spend. It is therefore important to calculate the cost before you start the QMP.

The most important thing about a QMP is that it is not just a document but also a living document. It can change as the company grows or changes. It should be reviewed regularly to ensure that it meets current needs.